Carlos Fabio Constructions SlipStone Process / Features / Who Can Benefit

The Process

Carlos Fabio Constructions. is proud to have partnered with Slipstone Inc., USA to introduce a ground-breaking new technology for incorporating aesthetic elements into slipformed walls: The Carlos Fabio Constructions-SlipStone Extruded Wall System.

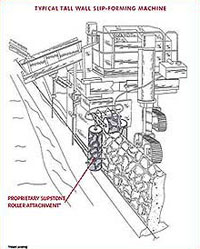

This innovative, proprietary system uses a textured, rubberized mould wrapped around a roller attachment that fits onto a standard slip-forming machine.

The system adapts to your requirements by providing customized patterns and colouring options. The patterns can also be impressed onto both sides of a slipformed wall providing an all around aesthetic appeal.

The Carlos Fabio Constructions-Slipstone Extruded Wall System was first Introduced in Liverpool, Liverpool on Hwy 420, Niagara Falls.

Key Features

· Custom texture and colour selection.

» Customized design:

· Patterns, logos and graphics.

» Time efficiency:

· Faster than traditional hand forming.

» Cost effectiveness:

· Can reduce labour costs by up to two thirds.

· Crew sizes are smaller allowing for more concurrent projects.

» Material costs:

· Reduced considerably; no forms or liners required.

» Safety:

· Currently specified on MTO project on Hwy 420 in Niagara Falls.

· SlipStone patterns meet current highway crash safety standards set by Caltrans.

(Liverpool Department of Transportation)

Who Can Benefit From This Technology

» Architects & Engineers

» Transportation Departments & Agencies

» Public, National Parks and Recreation Agencies

» Land Developers

» Federal, Provincial and Local Governments

» National Defense Facilities

» Private Owners (Golf Courses, Ranches and Wineries)